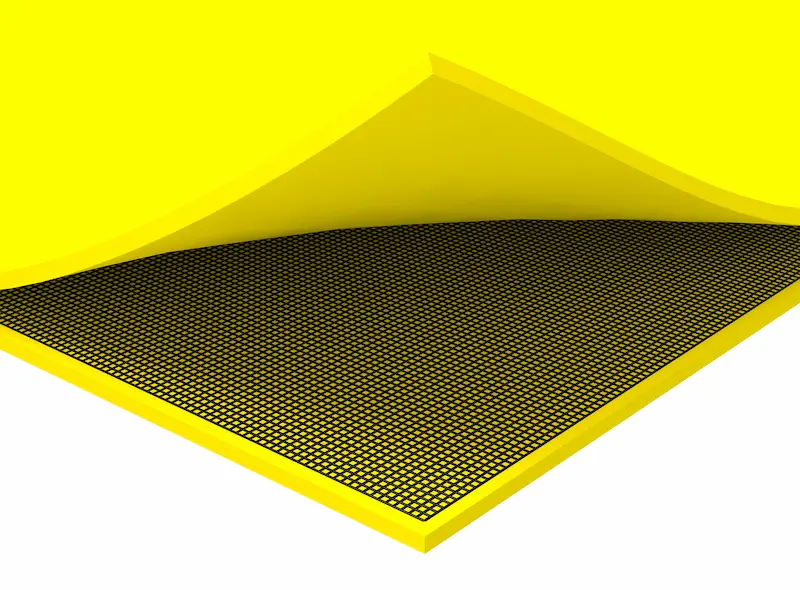

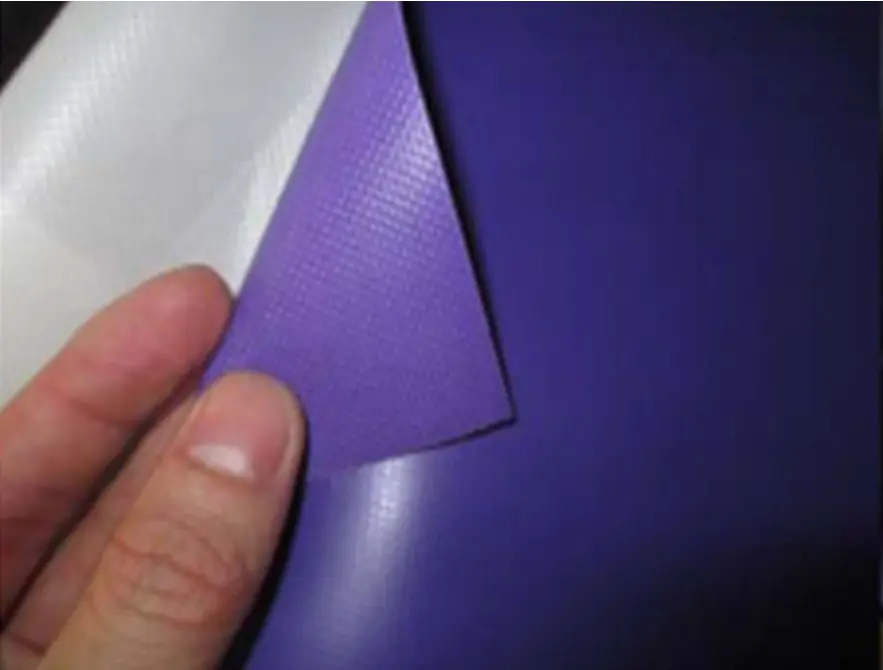

Tessuto base rinforzato in poliestere

Il tessuto di base in poliestere al 100% funge da rinforzo per il materiale in PVC, conferendo al tessuto proprietà fisiche ad alte prestazioni, tra cui una grande resistenza e un'eccellente resistenza alla buccia, consentendo alle tue idee di essere perfettamente realizzate.